Aurora Inverter Program Table Calculations

If you have a programmable inverter you probably want to know how to calculate the points on the curve so the inverter knows how much energy to extract at a given wind speed. The generator's open voltage is directly proportional to the RPM, which is proportional to the wind speed. The Aurora inverter uses the voltage input in order to determine how much current to draw, allowing one to program the input power for wind speed. The inverter will use the data points to extrapolate the power curve.

So how do you know how much current to draw at each voltage point? First, we need an equation. If you look below at the figure I derived a means of determining the current one can draw for a given voltage in order to equal the wattage available at that voltage. Remember, the voltage tells us how fast the turbine is turning; how fast the turbine turns is proportional to the power availble.

Vo is the open voltage, Ri is the generator impedance and R is the load imposed by the inverter. The current, I, depends on the total system impedance, which is (Ri + R). The generator voltage, under load, is determined by the ratio of the load and generator impedance. Using these basic formulas, one comes up with Wattage = Vo^2 x R/ (R+Ri)^2

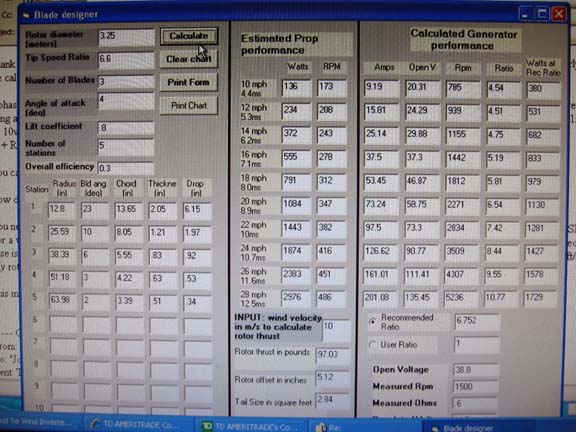

I first determine the open voltage at a set RPM and solve for the constant k. I can now calculate the voltage at any RPM using the formula Vo = k*RPM. Knowing the TSR, I can get a rough idea of the wind speed if I know the RPM. Now, the wind turbine is not 100% efficient, so you need to make a realistic determination of the efficiency of the whole system. Let's say we expect to get 30% of all of the available wind energy. The TSR of my 10.5' rotor is 6.6. I determined that:

Vo = 0.6456*RPM

When the RPM is 208 there is 780 wattage available. Thirty percent is 234 watts. The open voltage at 208 RPM is 134v. I measured the impedance of my generator to be approximately 5.5 ohms. I now need to determine by trial and error what load, R, will satisfy the equation

234 = 134^2* R/ (R + 5.5)^2

I got a load of 64 ohms. The current the inverter can draw is 1.93A and the output voltage will be 124v. Now I can generate a table like the one below.

I use V (not Vo) and W30 for my power curve points. You can experiment by trying various efficiencies. You might find that your turbine is more or less efficient than your initial guess.

You can run through the calculations for getting wind power and rpm by hand, but a blade design program helps. I will show you how to do the calculations by hand, and then I will just show a computer generated table.

Let's say you have a 12mph wind and your rotor diameter is 10.5 feet (circumference = 10.5*pi), the TSR is 6.6 and efficiency is 30%

The maximum theoretical wind power available is 780W. 30% is 234W.

12.5 mph winds means the blade tips are moving; 12.5mi/hr * 5280 ft/mi / 60 min/hr = 6952 ft/min. If the rotor is 10.5*pi feet the rotor is moving 6952/32.99 = 210 rev/min